Products List

- Stainless Steel Pipe Making Machine

- Decorative Stainless Steel Pipe Making Machine

- Industrial Stainless Steel Pipe Making Machine

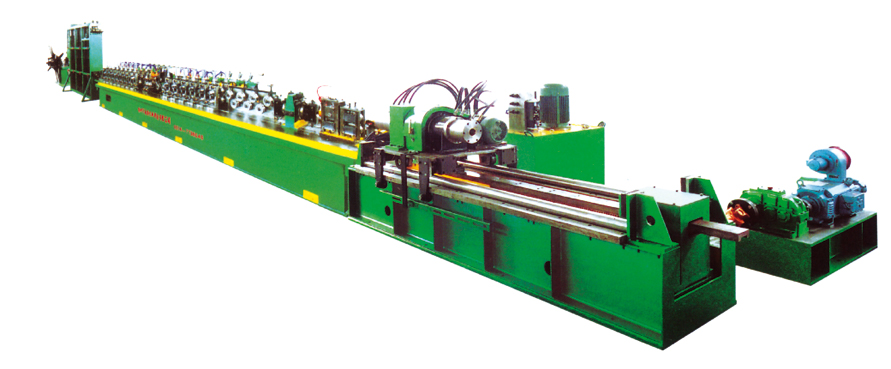

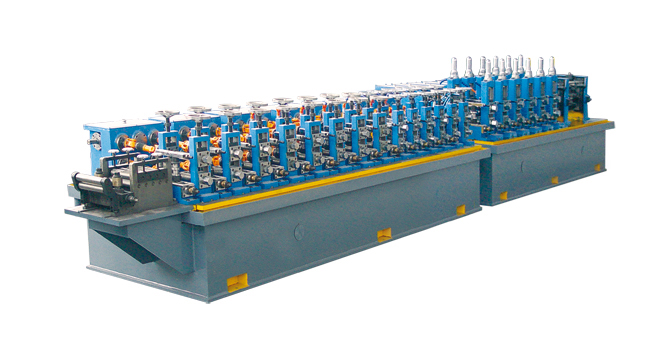

- Carbon Steel Welded Pipe Production Line

- Spiral Welded Pipe Production Line

- Complete Spiral Welded Pipe Production Line

- Spiral Pipe Production Line

- Spiral Welded Pipe Mills

- Completed Spiral Welded Tube Mill

- Double metal composite welded pipe mill/production line

- Stainless steel welded pipe mill/production line

- Welded Pipe Mill

- Straight Seam Welded Pipe Mill

- Straight Seam SubmergedArc Welded Pipe Mill

- Straight Seam HF Welded Pipe Mill

- Spiral Welded Pipe Mill

- Cold Roll Forming Steel Mill

- Square Pipe Mill

- Section Steel Mill

- Slitting Line

- Cut To Length Line

- Hydrostatic Testing Machine

- Spiral Welded Pipe Hydrotester

- Straight Seam Welded Pipe Hydrotester

- Seamless Pipe Hydrotester

- End Facing and Beveling Machine

- Spiral Welded Pipe End Facing and Beveling Machine

- Straight Seam Welded Pipe End Facing and Beveling Machine

- Steel Pipe Wrapping Machine

- Tube Straightening Machine

Contact US

Hangzhou Roll Forming Metallurgy Complete Equipment Co., Ltd

Add: Room 1601, 1st Building, Taifu Plaza, No.1 Tonghui Middle Road, Xiaoshan, Hangzhou City, Zhejiang, China

Tel: +8657182897908

Email:

info@roll-forming.cn

betty@roll-forming.cn

betty-yang1987@hotmail.com

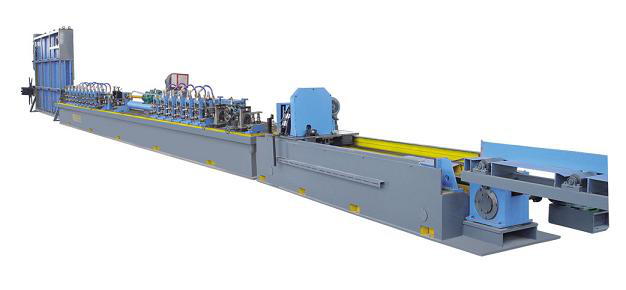

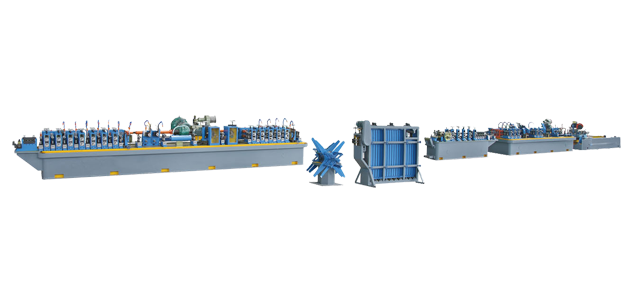

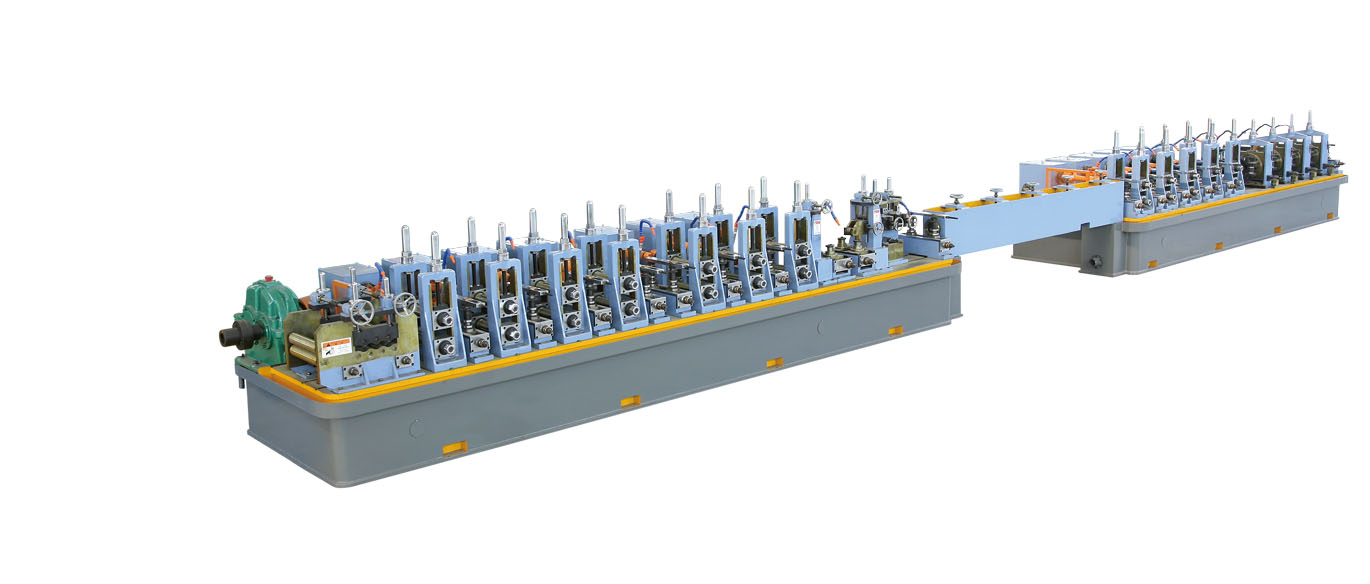

Carbon Steel Welded Pipe Production Line

Description

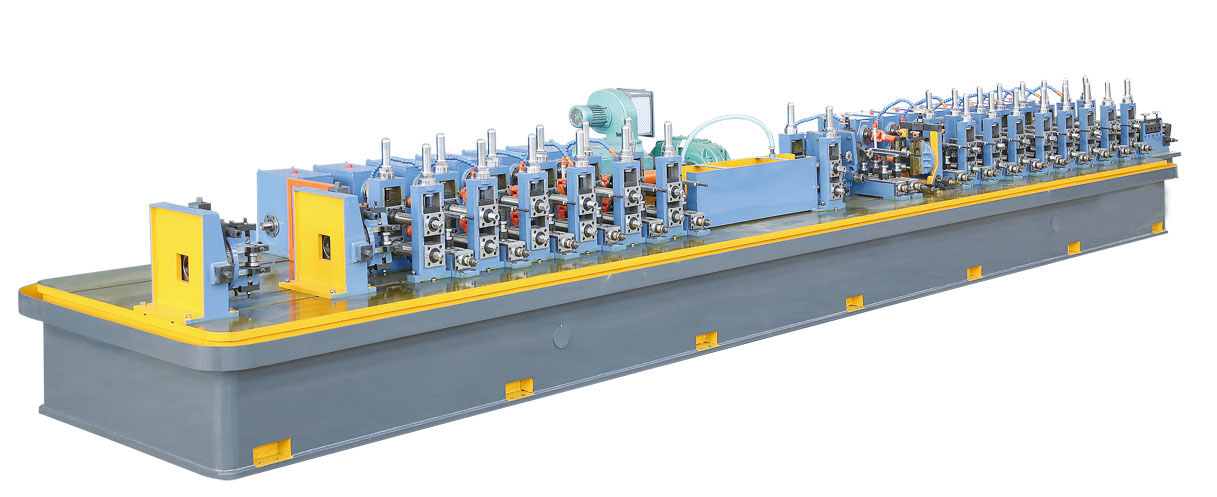

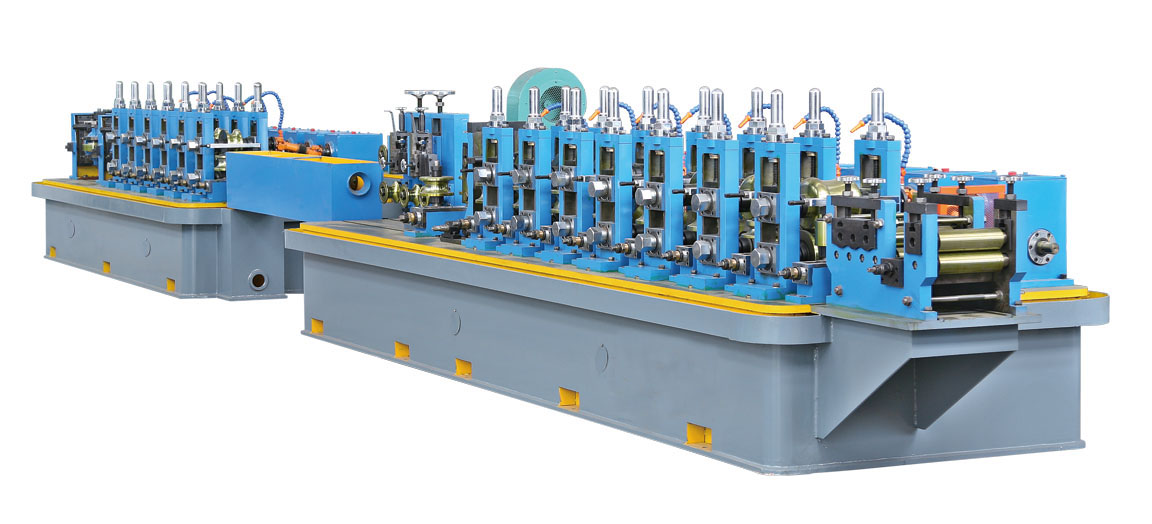

We can design and manufacture different series of welded pipe roll forming machine (welded pipe mill) for producing high quality straight seam welded pipes (carbon steel) and the corresponding square pipes, rectangular pipes, as well as special shape pipes. We use refined raw material and complete fabrication process such as edging therefore our tube mills/pipe mills are more reliable than those who don't take such process. Our pipe mills and tube mills have the advantages including high precision, long lifespan, high reliability, and less bugs in running. The whole machine mainly consists of uncoiler, roll forming device, high frequency welding part, computer fixed length cutting device (or flying cutting device), run out table. Finished pipe packing machine can be supplied as well on customer's request. We're an industry leader in China in both quality and business scale. In our factory, you can see why our welded pipe roll forming machines/tube mills are so popular among the manufacturers of high quality straight seam welded pipes/tubes.

The following machines introductions are just for examples

1.12/16/25/28 Straighten Seam & High Frequency Welded Pipe Production Line

This welded pipe roll forming machine mainly consists of uncoiler, shearing & buttwelder, vertical accumulator, forming, welding, sizing machine, computer cutting saw, runout table.

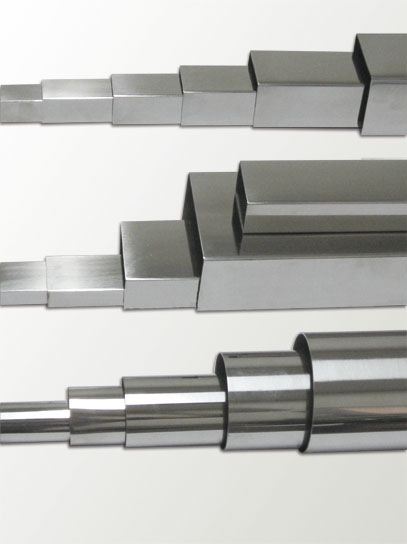

Finished Products Display

Process Flow

Uncoiler→Shearing & buttwelder→Vertical accumulator→Forming, welding, sizing machine→Computer cutting saw→Runout table

Technical Parameter:

| Specification | ZG12 | ZG16 | ZG25 | ZG28 |

| Diameter of Welded Tube | Φ716mm | Φ825mm | Φ830mm | Φ1038mm |

| Wall thickness of Welded Tube | 0.20.5mm | 0.31.0mm | 0.41.3mm | 0.51.5mm |

| Speed of Tube Welding | 50100M/min | 50100M/min | 50100M/min | 5090M/min |

| Power of Major motor | 15KW | 22KW | 37KW | 55KW |

| Power of High Frequency Welder | 60KW | 60KW | 100KW | 10KW |

Note: We can design it as per customers' requirements in terms of specification and configuration.

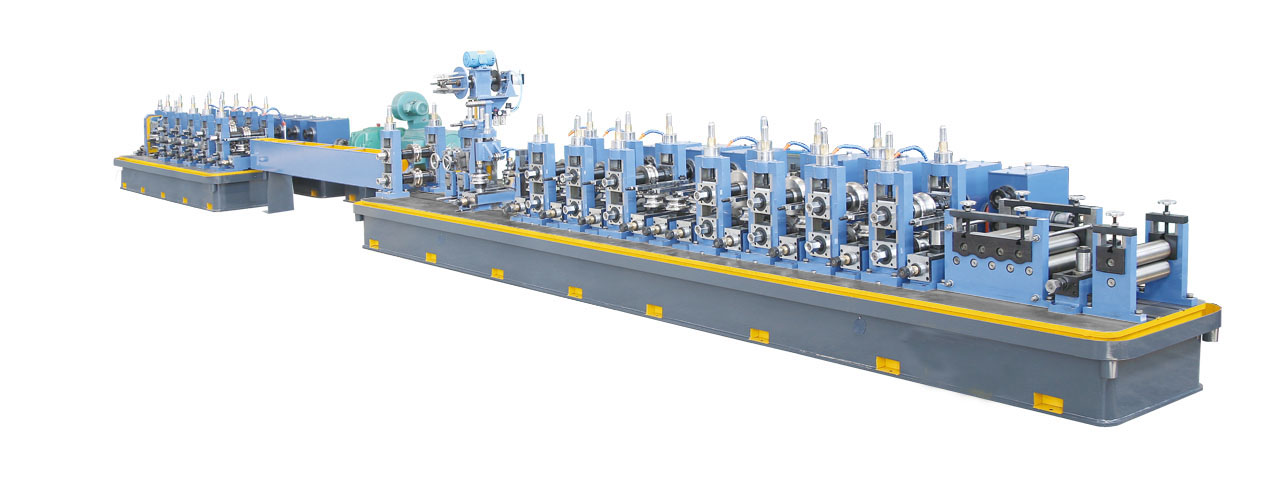

2.32 High Precision & High Frequency Welded Pipe Production Line

This welded pipe roll forming machine mainly consists of uncoiler, shearing & buttwelder, vertical accumulator, forming, welding, sizing machine (Including 2 sets of Turkey head straightening device), computer cutting saw, runout table.

Process Flow

Uncoiler→Shearing & buttwelder→Vertical accumulator→Forming, welding, sizing machine (Including 2 sets of Turkey head straightening device)→Computer cutting saw→Runout table

Technical Parameter:

| Specification | ZG32 tube mill line |

| Diameter of Welded Tube | Φ1350.8mm |

| Wall thickness of Welded Tube | 0.62.0mm |

| Speed of Tube Welding | 5090M/min |

| Power of Major motor | 90KW |

| Power of High Frequency Welder | 100KW |

Note: We can design, develop & produce products according to clients’ requirements.

3.50/60 Straighten Seam & High Frequency Welded Pipe Production Line

This welded pipe roll forming machine mainly consists of uncoiler, shearing & buttwelder, accumulator, forming machine, water cooling tank, sizing machine, computer cutting saw, runout table.

Process Flow

1. Uncoiler→Shearing & buttwelder→Vertical accumulator→Forming machine→Water cooling tank→Sizing machine→Computer cutting saw→Runout table

2. Hydraulic uncoiler→Shearing & buttwelder→Horizontal accumulator→Forming machine→Water cooling tank→Sizing machine→Cold saw→Runout table

Technical Parameter:

| Specification | ZG50 | ZG60 |

| Diameter of Welded Tube | Φ1563.5mm | Φ1663.5mm |

| Wall thickness of Welded Tube | 0.82.5mm | 1.03.0mm |

| Speed of Tube Welding | 4080M/min | 4080M/min |

| Power of Major motor | 110KW | 132KW |

| Power of High Frequency Welder | 150KW | 200KW |

Note: We can design, develop & produce products according to clients’ requirements.

4.76/90 Straighten Seam & High Frequency Welded Pipe Production Line

This welded pipe roll forming line mainly consists of uncoiler, shearing & buttwelder, horizontal accumulator, forming machine, water cooling tank, sizing machine, computer cutting saw, runout table.

Process Flow

1. Hydraulic uncoiler→Shearing & buttwelder→Horizontal accumulator→Forming machine→Water cooling tank→Sizing machine→Computer cutting saw→Runout table

2. Hydraulic uncoiler→Shearing & buttwelder→Horizontal accumulator→Forming machine→Water cooling tank→Sizing machine→Cold saw→Runout table

Technical Parameter:

| Specification | ZG76 | ZG76 enlarge toΦ127 | ZG90 | ZG90 enlarge toΦ140 |

| Diameter of Welded Tube | Φ2580mm | Φ32127mm | Φ32100mm | Φ60140mm |

| Wall thickness of Welded Tube | 1.24.0mm | 1.52.5mm | 1.54.5mm | 1.54.0mm |

| Speed of Tube Welding | 3070M/min | 3060M/min | 2060M/min | 2060M/min |

| Power of Major motor | 160KW | 90KW×2 | 110KW×2 | 132KW×2 |

| Power of High Frequency Welder | 300KW | 350KW | 350KW | 400KW |

Note: We can design, develop & produce products according to clients’ requirements.

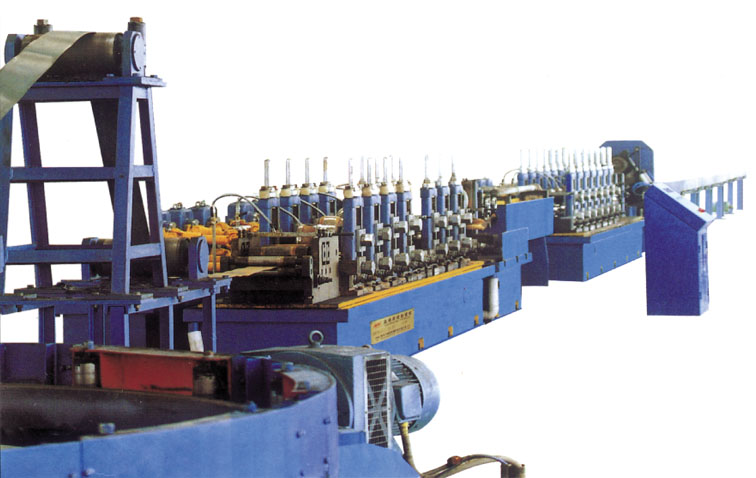

5.115/219 Straighten Seam & High Frequency Welded Pipe Production Line

This welded pipe roll forming machine mainly consists of uncoiler, straightening machine, powerful leveling machine, shearing & buttwelder, horizontal accumulator, forming machine, water cooling tank, sizing machine, computer cutting saw, runout table.

Process Flow

Hydraulic doublecone uncoiler→Straightening machine→Powerful leveling machine→Shearing & buttwelder→Horizontal accumulator→Forming machine→Water cooling tank→Sizing machine→Computer cutting saw→Runout table

Technical Parameter:

| Specification | ZG115 | ZG165 | ZG219 |

| Diameter of Welded Tube | Φ40115mm | Φ76165mm | Φ114219mm |

| Wall thickness of Welded Tube | 1.55.0mm | 2.06.0mm | 3.08.0mm |

| Speed of Tube Welding | 1560M/min | 1550M/min | 1540M/min |

| Power of Major motor | 132KW×2 | 185KW×2 | 250KW×2 |

| Power of High Frequency Welder | 400KW | 600KW | 800KW |

Note: We can design, develop & produce products according to clients’ requirements.

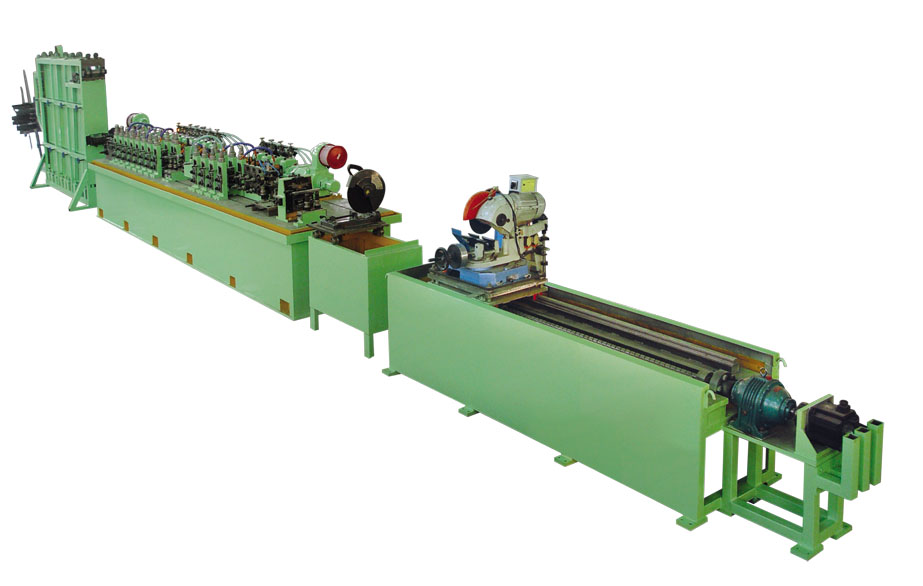

6.20/30 Highprecision Plastic Tube Welding Line

This welded pipe production line mainly consists of uncoiler, shearing & buttwelder, accumulator, forming ,welding, sizing machine, plastic composing machine, computer cutting saw, runout table

Process Flow

Uncoiler→Shearing & buttwelder→Vertical/horizontal accumulator→Forming, welding, sizing machine→Plastic composited machine→Computer cutting saw→Runout table

Uncoiler→Shearing & buttwelder→Vertical accumulator→Forming, welding, sizing machine→Plastic composing machine→Computer cutting saw→Runout table

Technical Parameter:

| Specification | FG20 | FG30 |

| Diameter of Welded Tube | Φ825.4mm | Φ1332mm |

| Wall thickness of Welded Tube | 0.30.5mm | 0.40.8mm |

| Speed of Tube Welding | 1035M/min | 1035M/min |

| Power of Major motor | 15KW | 22KW |

| Power of High Frequency Welder | 60KW | 60KW |

Note: We can design, develop & produce products according to clients’ requirements.

7.GW Series rollforming Machine

This welded pipe production line mainly consists of uncoiler, shearing & buttwelder, forming machine, computer cutting saw, runout table.

Process Flow

Uncoiler→Shearing & buttwelder→Forming machine→Computer cutting saw→Runout table

Technical Parameter:

| Specification | GW series rollforming machine | ||||

| GW150 | GW200 | GW250 | GW300 | GW350 | |

| Milling | 50150mm | 50200mm | 50250mm | 100300mm | 100350mm |

| Milling Thickness | 0.51.2mm | 0.81.5mm | 1.02.0mm | 1.22.5mm | 1.53.5mm |

| Milling Speed | 525M/min | 525M/min | 520M/min | 520M/min | 515M/min |

| Power of Major Motor | 22KW | 30KW | 37KW | 45KW | 75KW |

Note: We can design, develop & produce products according to clients’ requirements.

Related Products

- Spiral Welded Pipe Mill

- The steel plates in certain width after slitting and stripping are unfolded and leveled and then sent into a forming machine. By using the roller ...

- Square Pipe Mill

- Square pipe making machine is complete equipment that processes the siphonula into square pipes. The main procedure is that the rolling plate ...